Self-connecting vibration crystallizer:

The overall structure is more compact and the size is much smaller than the traditional design, reducing the weight of the vibrating table system equipment.

The mold "copper tube, inner water jacket and mold upper flange" vibrates. The mold box itself, cooling water, vibrating table, and electromagnetic stirring coil are all fixed. Compared with the traditional design, the dynamic gravity is reduced by 95%, so the vibration frequency and vibration accuracy are greatly improved.

High-precision vibration can significantly reduce the depth of vibration marks on the billet surface, improve the surface quality of the cast billet, and increase the service life of the mold copper tube.

Low maintenance costs.

The vibration drive source is a servo hydraulic cylinder, which drives the vibrating arm to vibrate; the flexible hydraulic control system can change the vibration frequency and amplitude during the casting process to optimize the negative slip time and negative slip rate; at the same time, the control system can realize online selection vibration curve, such as sinusoidal, deformed sinusoidal and triangular curve and other non-sinusoidal vibration modes.

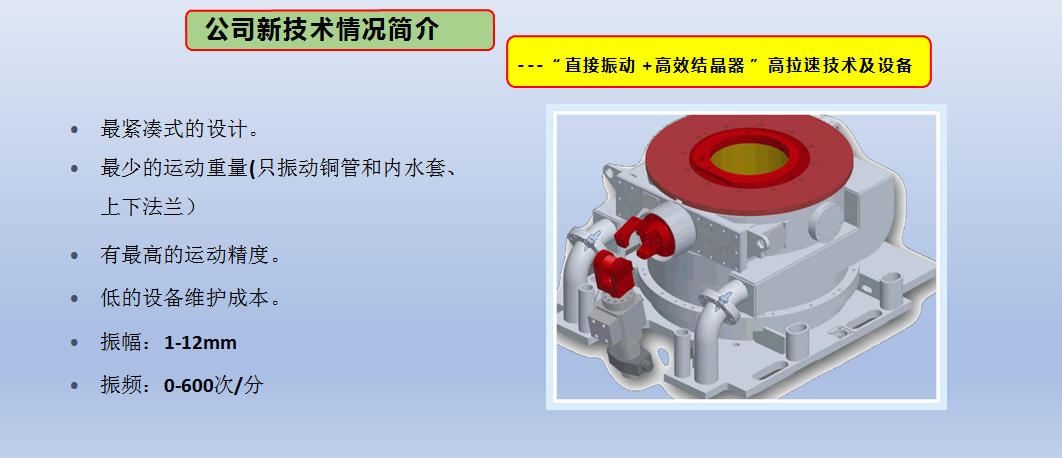

Introduction to the company's new technology "Direct vibration + high efficiency mold" high-speed technology and equipment

The most compact design

Minimal movement weight (only vibrating copper pipe and inner water jacket, upper and lower flanges)

Have the highest movement accuracy

Low equipment maintenance costs

Amplitude: 1-12mm

Vibration frequency: 0-600 times/min

Billet high-speed drawing technology:

The high-speed billet solution is suitable for the section of 150-200 billet of ordinary carbon steel, and the high-speed range is 3.0-6.5 meters. It has technical and project cooperation with Danieli Company of Italy and Comcast Company of Switzerland:

1. Optimize the mold assembly, using grooved copper tube technology, fixed water gap diversion water jacket technology, etc.;

2. Extend the secondary spray cooling interval;

3. Adopt high pressure and high density nozzle arrangement form;

4. The tundish pouring nozzle adopts automatic flow control technology that changes according to the pulling speed;

5. Whole-process temperature measurement system for continuous casting billet;

6. Adaptive water distribution control system.

At present, the casting billet with 160x160 section has been realized, and the production speed can be stabilized at 4.5m/min. In the future, through continuous technical updates, a speed level above 5.0m/min will be achieved.

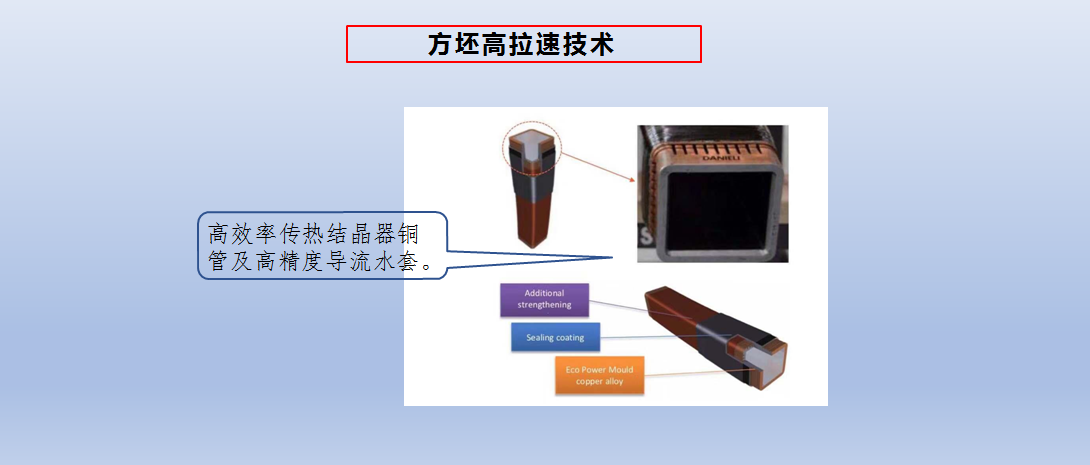

Billet high-speed drawing technology

Precisely machined inner water jacket, expensive

The water tank is processed on the outer wall of the copper pipe to increase the heat exchange area and ensure high drawing speed

High-efficiency heat transfer mold copper tube and high-precision diversion water jacket

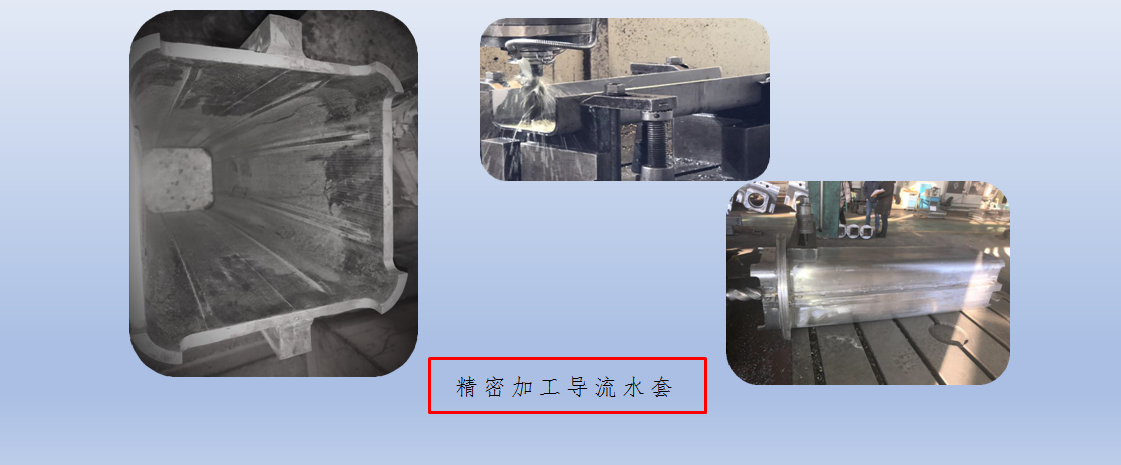

Production of precision machining diversion water jacket

Precisely machined inner water jacket, expensive

Production of precision machining diversion water jacket

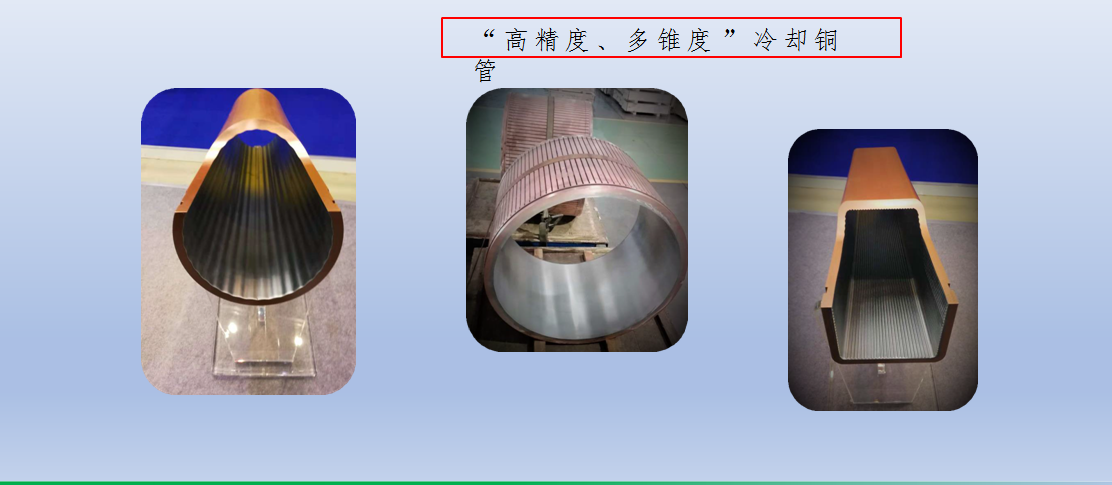

"High-precision, multi-dimensional" cooling copper pipe

High cooling strength copper pipe

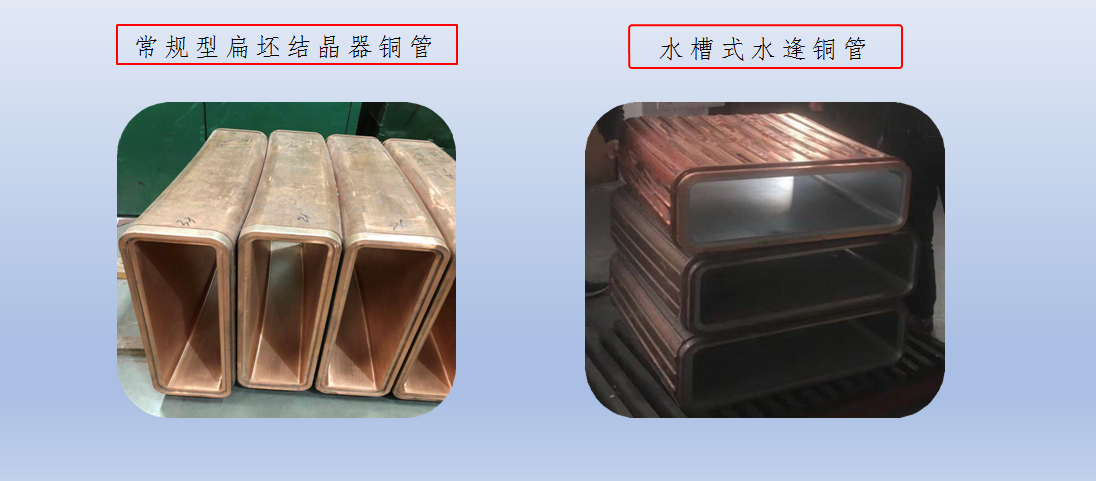

Conventional slab mold copper tube

Sink type water meeting copper pipe

Copper tube water jacket integrated crystallizer